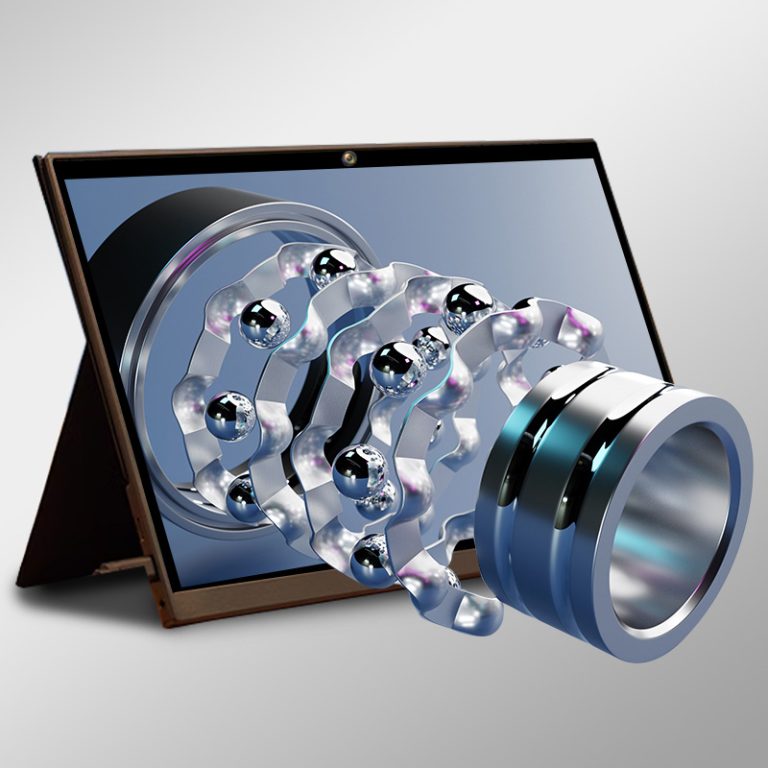

The 3D lens manufacturer industry is at the cusp of significant evolution, driven by advancements in technology and an increasing demand for applications across sectors such as augmented reality (AR), virtual reality (VR), and industrial automation. With market projections expecting the global 3D lens industry to reach $12.5 billion by 2030, growing at a compound annual growth rate (CAGR) of 8.5%, the trajectory appears promising for manufacturers.

Current Trends Shaping 3D Lens Manufacturers

1. Increasing Demand from AR and VR Markets

The rise of 3D lens manufacturers has been catalyzed by the explosive growth in AR and VR markets. These technologies rely heavily on high-precision lenses for creating immersive experiences:

- The AR and VR market is expected to grow from $37 billion in 2022 to $114 billion by 2027.

- This surge necessitates innovation in lens manufacturing, emphasizing reduced weight, higher resolution, and increased durability.

Moreover, many manufacturers are exploring hybrid lens systems to enhance image clarity and depth perception, crucial for next-generation VR headsets.

2. Adoption in Industrial Applications

Beyond entertainment, industrial sectors are leaning heavily on 3D lenses. For example, 3D machine vision, used in quality control and automation, saw a 12% growth in 2024 alone. 3D lens manufacturers are innovating to meet the demand for compact, high-performance lenses:

- Improved depth-of-field for machine vision systems.

- Enhanced durability for harsh industrial environments.

- Cost-efficiency, driven by precision manufacturing techniques.

Technological Innovations Driving Growth

1. Advanced Materials and Coatings

One major development area for 3D lens manufacturers lies in material science. Recent innovations include:

- Anti-reflective and anti-scratch coatings to extend lens lifespan.

- Incorporation of lighter materials, such as polymer-based lenses, which reduce weight by up to 40% compared to glass counterparts.

2. Integration with AI

Artificial intelligence (AI) is significantly impacting the design and production of 3D lenses. By leveraging AI algorithms:

- Lens distortions during production can be reduced by 20%.

- Predictive modeling allows manufacturers to optimize designs for specific industries, such as automotive or medical imaging.

Challenges and Opportunities in Expansion

1. Challenges Faced by 3D Lens Manufacturers

- Cost Constraints: Advanced manufacturing techniques raise production costs by up to 15%.

- Complex Customization Needs: Industries like healthcare require lenses with micron-level precision, increasing the burden on R&D budgets.

- Global Supply Chain Issues: Fluctuations in raw material availability can delay production schedules by several months.

2. Opportunities for Growth

However, 3D lens manufacturers are also positioned to seize numerous opportunities:

- Expansion into emerging markets in Southeast Asia, where demand for AR and VR applications is projected to grow by 25% annually.

- Collaboration with tech giants to integrate cutting-edge lenses into consumer devices, such as smartphones and wearable devices.

3. The Road Ahead for 3D Lens Manufacturers

The future development of 3D lens manufacturers lies in their ability to adapt to rapid technological advancements and diversify their applications. By 2030, we may witness:

- An estimated 30% reduction in production costs through automation.

- The introduction of “smart lenses” capable of self-correcting distortions in real-time.

- Increased use of sustainable practices in manufacturing to reduce carbon footprints, meeting global sustainability goals.

As the demand for high-performance 3D lenses continues to grow, 3D lens manufacturers that embrace innovation, diversify their applications, and enhance efficiency will undoubtedly shape the future of this transformative industry.