Introduction: The Role of 3D Display Technology in Industrial Transformation

3D display technology has emerged as a cornerstone of the digital materialization revolution, bridging the gap between virtual models and physical industrial processes. By enabling high-fidelity visualization and real-time interaction, this technology accelerates the adoption of digital twin materialization—a concept where virtual replicas of physical systems drive optimization and innovation across industries. With the 3D display sector poised to reach a global valuation of $161.45 billion by 2025 (exhibiting a CAGR of 20.4%), this technology is fundamentally transforming industrial workflows across manufacturing, product design, and predictive maintenance paradigms.

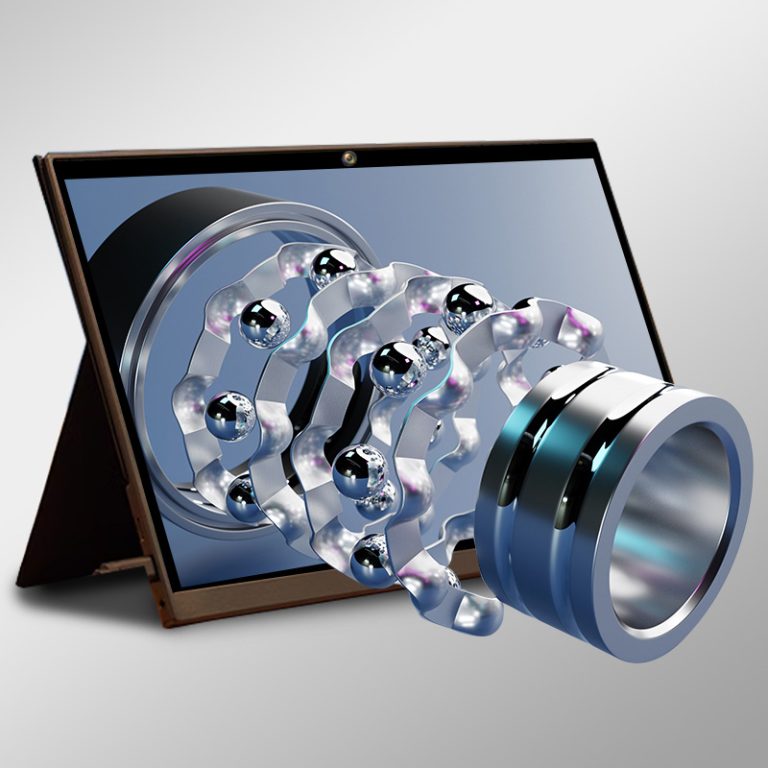

1. 3D Display Technology as the Visual Engine for Digital Twins

1.1 Real-Time Synchronization and Visualization

3D displays transform abstract data into tangible insights, critical for digital twin applications. For instance:

- Industrial Monitoring: Systems like those developed for robotics integrate 3D displays to visualize real-time operational data, reducing error rates by 30% through immersive diagnostics.

1.2 Enhancing Collaborative Design

Architects and engineers leverage 3D displays to review designs in AR/VR, enabling:

- Faster iterations: SHoP Architects reduced design review cycles by 50% through real-time 3D modeling.

- Cross-disciplinary alignment: Virtual showrooms allow stakeholders to explore product variants interactively.

2. Expanding Industrial Applications with 3D Display Technology

2.1 Smart Manufacturing and Automation

- Predictive Maintenance: Digital twins paired with 3D displays predict equipment failures, saving up to 20% in maintenance costs (e.g., GE’s wind turbines).

- Production Optimization: BMW improved assembly line efficiency by 15% via 3D-simulated layouts.

2.2 Healthcare and Education

- Surgical Planning: 3D-displayed patient twins enable personalized treatment simulations.

- Interactive Training: Medical students practice procedures in 3D environments, boosting accuracy by 25%.

3. Future Trends: Beyond Visualization

3.1 Glasses-Free 3D Displays

Emerging technologies like light-field displays (e.g., 120-degree viewing angle systems) eliminate hardware dependencies, broadening adoption in retail and teleconferencing.

3.2 Integration with Edge Computing and 5G

- Low-latency rendering: 5G networks enable real-time updates for digital twins, critical for autonomous factories.

- Scalability: Edge computing reduces data processing delays by 60%, enhancing 3D display responsiveness.

Conclusion: A Catalyst for Industrial Evolution

3D display technology is not merely a tool but a transformative force, materializing digital twins into actionable industrial assets. As the sector expands to a $332.9B valuation by 2029, its convergence with AI, 5G, and IoT will propel unparalleled operational agility and transformative breakthroughs, reshaping the paradigm of hyper-immersive digital-physical integration.